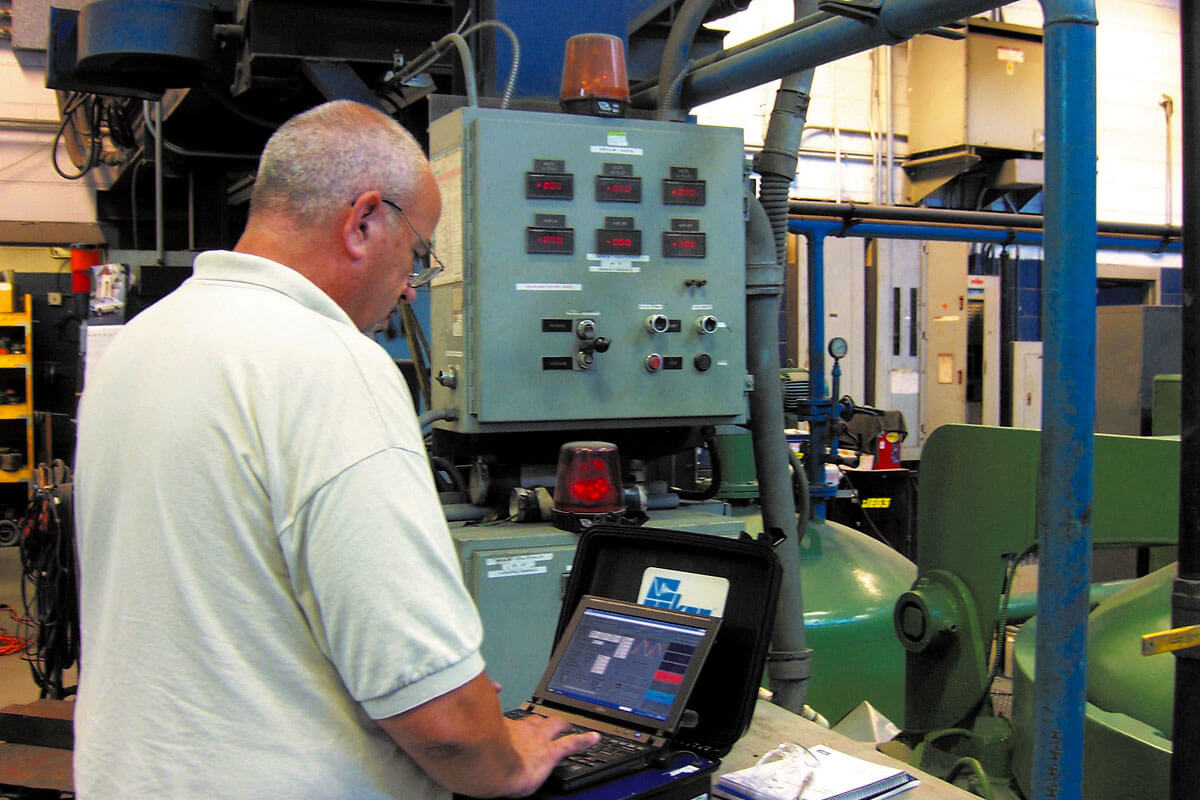

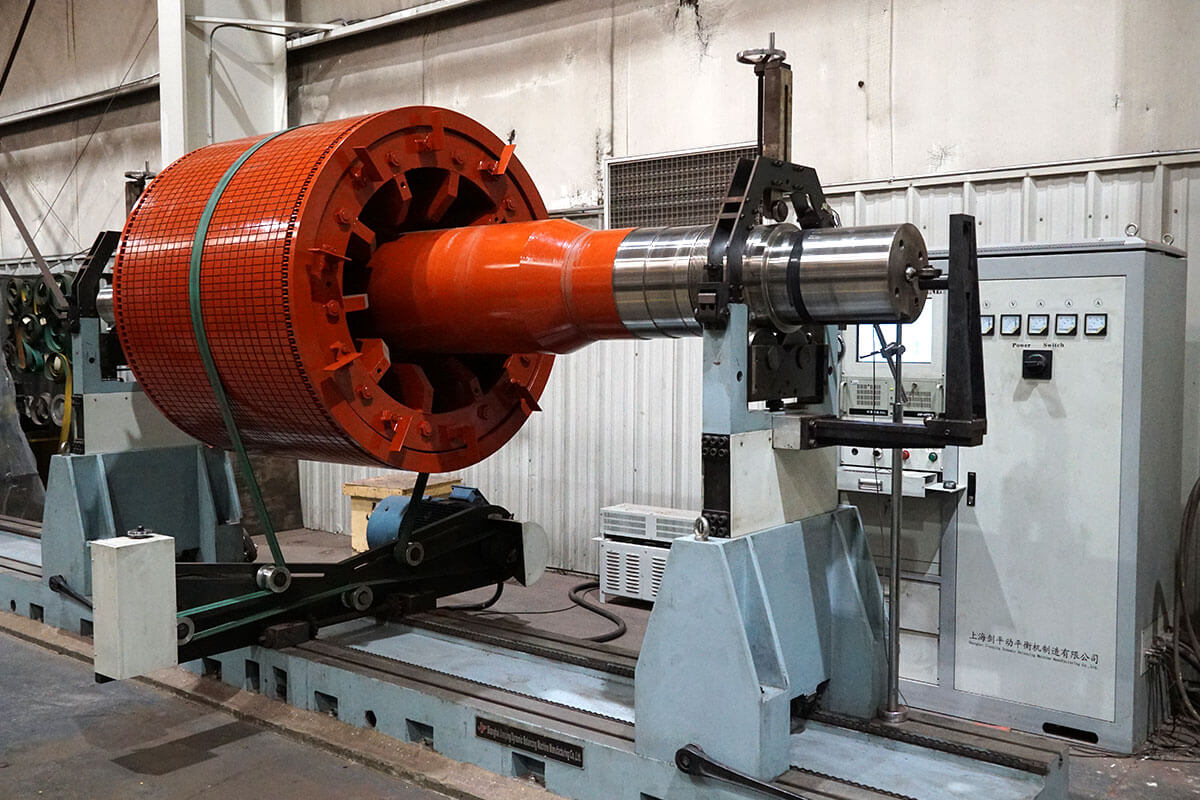

Identify possible issues. Monitor equipment changes. And minimize unexpected downtime. Smith Services® works onsite with your team to diagnose root causes of failure and maintain your equipment — before disaster strikes.

Our engineers, field service experts, and route drivers leverage our private fleet of service vehicles, plus over a half-century of combined expertise, to deliver the support you need, when you need it. Backed by our leading repair facility and preventative maintenance program, rest easy knowing your machines have the full support to run smoothly.

Sharpen your skills

Keep up with the latest in electric motor and generator technology by exploring our collection of training resources, whitepapers, and more.

Do your part to prevent catastrophic failureSpeak to one of our experts about preventative maintenance and diagnostic services today.

Contact us

Speak to one of our experts about preventative maintenance and diagnostic services today.